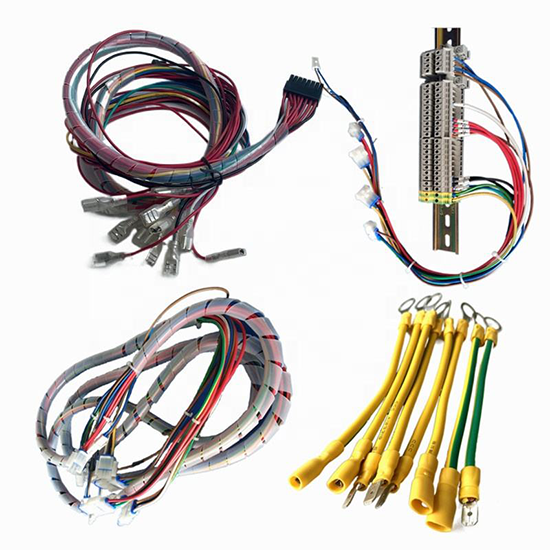

What Are Cable Assemblies?

A cable assembly is a specialized device that integrates individual wires and cables, serving the purpose of facilitating efficient and convenient transmission of electrical power or information signals. These assemblies hold significant importance across diverse industries, including modern electronics, construction machinery, and automotive applications. Not only do cable assemblies provide heightened protection against potential damage, vibration, and disconnection, but they also contribute to optimizing space utilization. The bundling of wires and cable harnesses within these assemblies enhances the effectiveness and reliability of transmission systems.

The principles and requirements for cable assembly component design

The design of cable assembly components encompasses the selection and matching of electrical connectors and wires, the matching of cable harnesses with electrical connectors, the allocation of electrical connector contacts, the structural design and installation of cable networks, product structure layout, as well as protection and reinforcement measures. These aspects are aimed at ensuring the cable design is manufacturable, maintainable, installable, and reliable.

Selection of Wires/Cables

Due to different equipment requirements and environments, wire and cable performance criteria vary, including temperature resistance, electromagnetic compatibility, fatigue resistance, flexibility, bending durability, tensile/compressive strength, vibration resistance, torsion resistance, solvent resistance, radiation resistance, flame retardancy, and fire resistance. Commonly used in low-frequency cable assemblies for airborne, automotive, and ground equipment are high-temperature resistant multicore cables, such as AF200, AF250, AFP series (traditional fluoroplastic high-temperature wires), Ruikang 55#, FF40J series (thin-walled aerospace wires), FF47 series (thin-walled wrap wires), and comprehensive cables combining these wires and cables.

Factors to Consider for Custom Cable Assemblies

Every project and equipment requires custom cable assemblies to connect and perform their functions. However, this task is neither easy nor cost-effective. Each cable has its unique application, and when selecting customizations, we need to consider the following factors: ①Delivery time for custom cable assemblies. ②Customizable features available. ③Superior quality of cable manufacturing and assembly products. ④High-level service and support.

Cable & Wire Assembly Applications

Automotive

Cable assemblies used in car electrical systems, sensors, dashboards, and entertainment systems.

Energy

Cable assemblies used in power plants, grids, transmission lines, and renewable energy systems.

Electronics

Cable assemblies for internal connections and data transfer in devices, computers, and appliances.

Aerospace

Cable assemblies for aircraft systems, navigation, communication, satellites, and spacecraft.

Industrial Automation

Cable assemblies used in robots, production lines, sensors, and control systems.

Medical

Cable assemblies used in medical equipment, imaging devices, surgical instruments, monitors, and sensors.

case

We provide an aerospace company with custom harness cable solutions for electrical systems for satellites and spacecraft. Through high temperature resistance, radiation resistance and vibration resistance, we ensure the reliability and stability of wire harness cables, ensuring the efficient operation of spacecraft in space. Our solutions enhance the safety, performance and reliability of spacecraft and contribute to the exploration and research of the space industry,Contact us now to receive a professional quote.